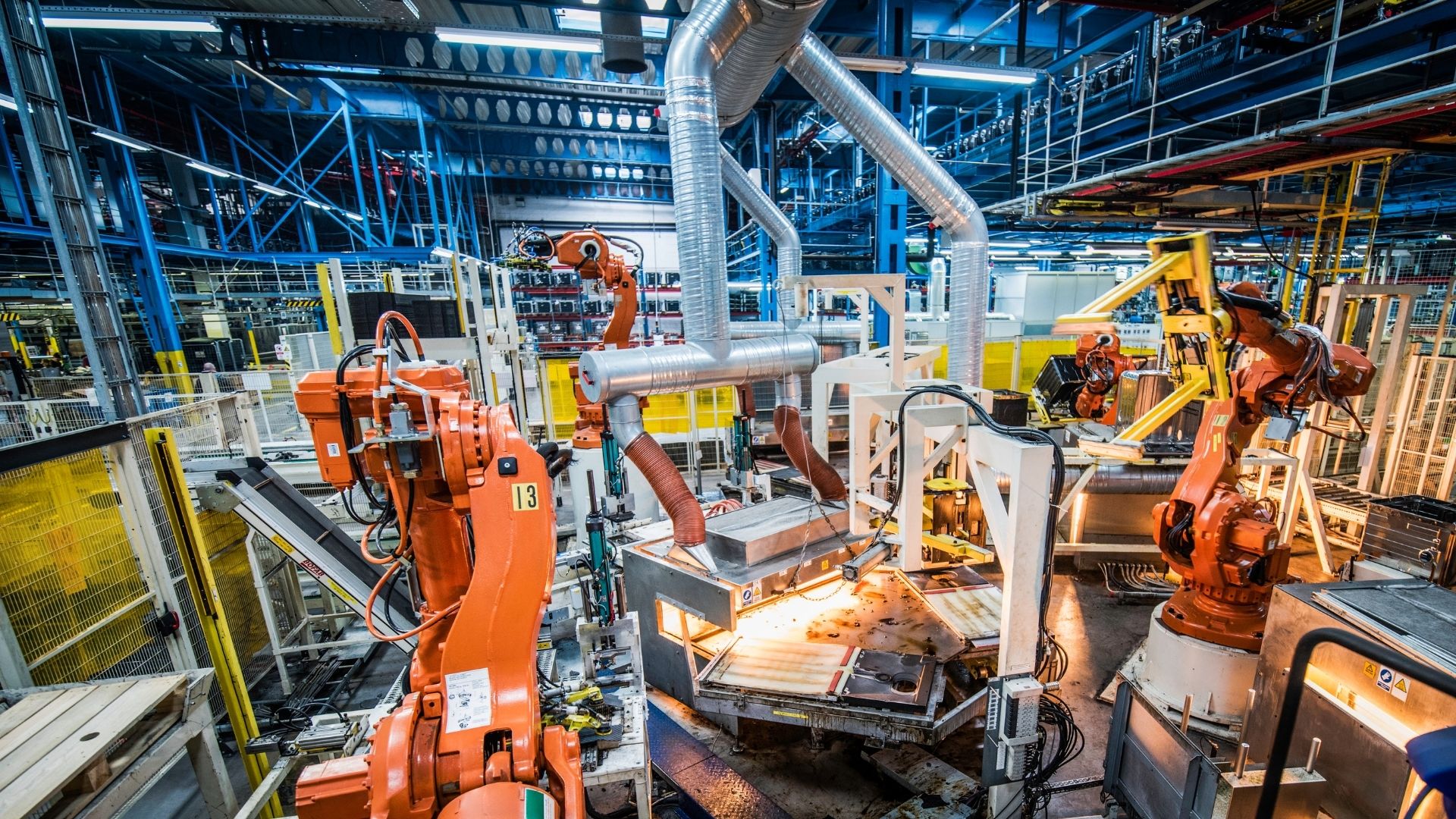

Manufacturing Excellence

Revolutionizing manufacturing through intelligent optimization

Allen Ralford Barkley's Manufacturing Excellence solutions transform traditional production environments into intelligent, data-driven operations. Our comprehensive approach combines advanced analytics, process optimization, and predictive insights to deliver unprecedented levels of efficiency, quality, and operational performance across all manufacturing sectors.